Accurate and reliable inspection Small changes on the conveyor belt Rich production statistics and defective products storage, tracking function

Product model: L-5100

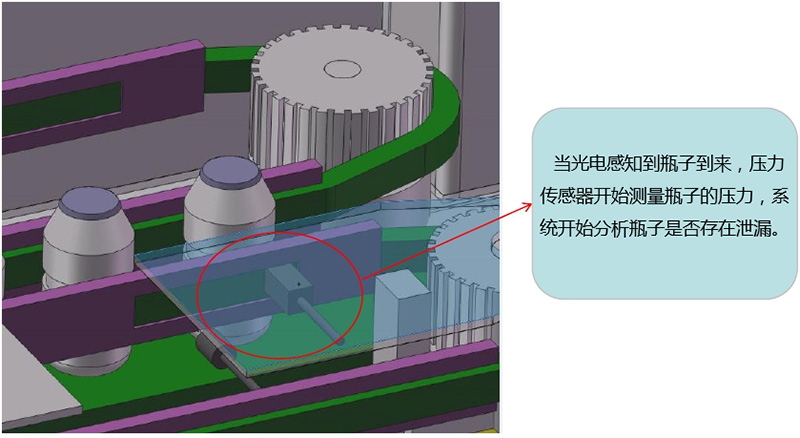

Installation position: between the filler and the sleeving machine

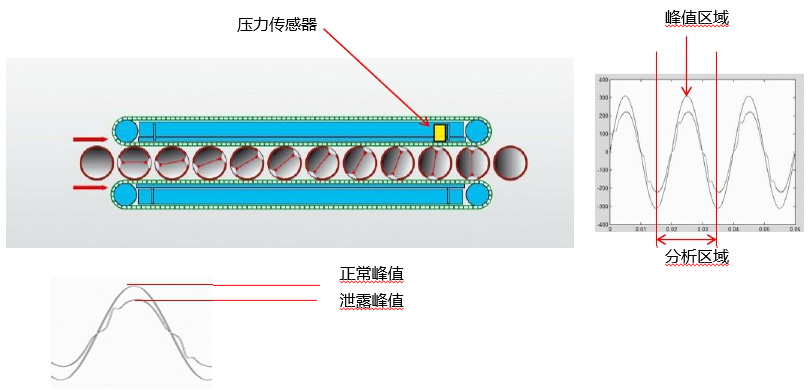

Inspection object: soft and deformable packing container

Inspection module: leakage, no cover, liquid level

Defective processing modes: single-stage pneumatic automatic rejecter

Maximum detection capability: 72000BPH

.jpg)